It was necessary to measure something ....

During the repair of the lathe, it became necessary to check the perpendicularity of the displacement of the transverse carriage to the axis of rotation of the spindle. I remembered that there is such a device, which in the Ukraine is called a "helicopter". Attempts to buy it did not lead to anything, and therefore it was decided to make it yourself.

Here I tried to describe in detail the manufacturing process with illustrations and explanations.

Choice straightedge.

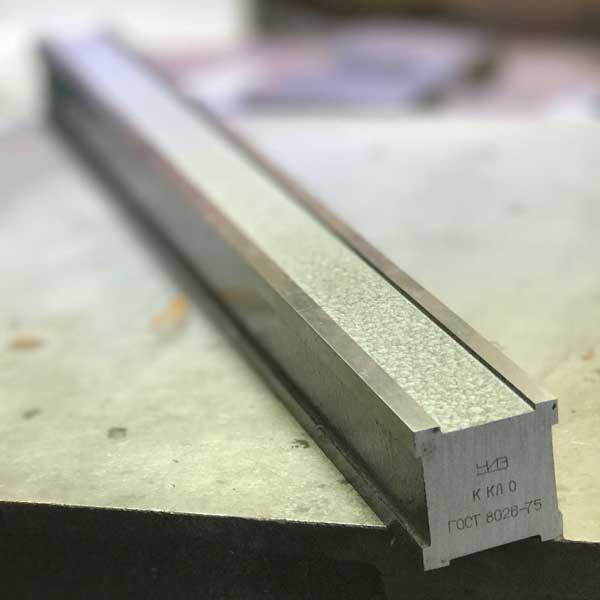

I had a tetrahedral engineer's knifeedge in my household. It should be said that the original uses a straightedge with a circular generatrix. So you can use a cylindrical test bar, if such is at hand. The length of the straightedge should allow it to turn 180 degrees above the bed. In principle, one of the ends may be longer and the other one shorter. You can use any kind of straightedge as you wish. Engineer's straightedges with a circular generatrix require measurement and alignment at the highest reading of the indicator, shaking (turning) the device. This is similar to the measurements of the hole-gauge, the principle is the same.

Straightedge.

Morse Taper.

Body billets.

A few words about the Morse Taper.

The Morse Taper MT4 was chosen for reasons of compatibility with the spindle. I took a conventional thrust center (braked with a beat about 0.1mm) cut with a milling machine and cut the thread with a die. In fact, there was no urgent need to do so. It is possible to use ready-made mandrels for mills or something like that. Even, the usual cylinder, if you have a collet chucks, quite will approach or suit. There are many options and the scope for creativity is huge.

Body.

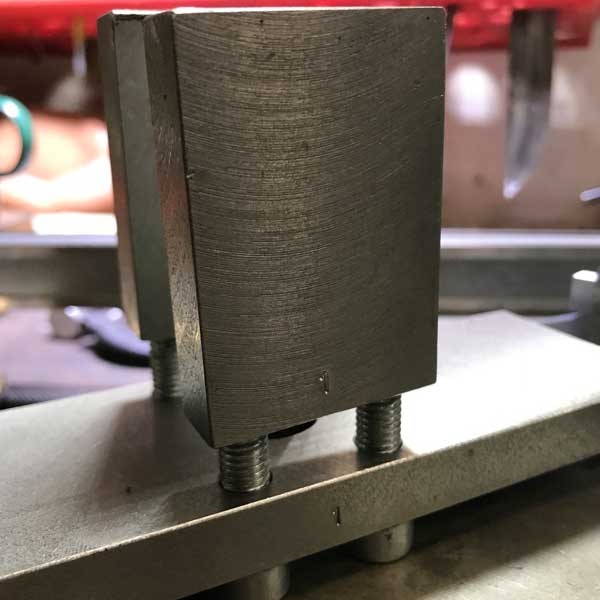

The body is made of three parts connected by screws M8. Requirements for the body - sufficient rigidity. The configuration is arbitrary.

Marking of body.

Making a shape.

Fitting.

Drill, thread, screw.

Assembling the body.

Screws of articulated straightedge.

Fixing the straightedge.

The straightedge is a piece of hardened steel, even very. Drilling through holes is not very pleasant. On the other hand, the fastening of the straightedge should allow for its rotation for accurate positioning perpendicular to the axis of rotation of the spindle. In my opinion, the best option is to drill two center holes with a carbide center bit and fix it on two screws with a conical shank. Screws from spontaneous unscrewing are screwed with a nut.

We drill a straightedge.

Control assembly.

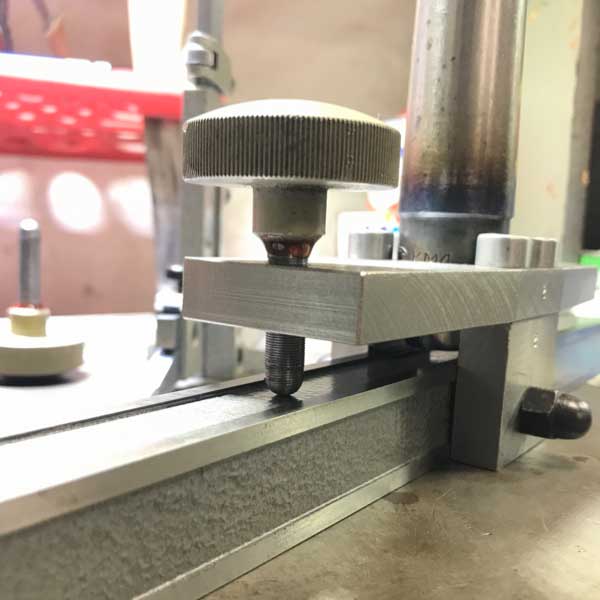

Adjusting screws.

And the last stage is the manufacture of adjusting screws. Here is one feature. The thread pitch should be minimal. This is necessary to ensure comfortable adjustment of the ruler. The smaller the pitch, the easier it is to align the ruler perpendicular to the spindle axis.

We form spherical tips.

Threading.

Install the handles on the thread lock.

In conclusion, I want to say that the device turned out to be excellent. Sufficiently tough, easy to use and easy to set up. Allows you to quickly check the direction of the cross carriage. And since the holes in the straightedge are made in non-working areas, if necessary, the straightedge can be removed from the device and used for its intended purpose.

That's all. Ask questions.